RCC Surface Pro TIS

A NEW DIMENSION FOR ROLLER COMPACTED CONCRETE

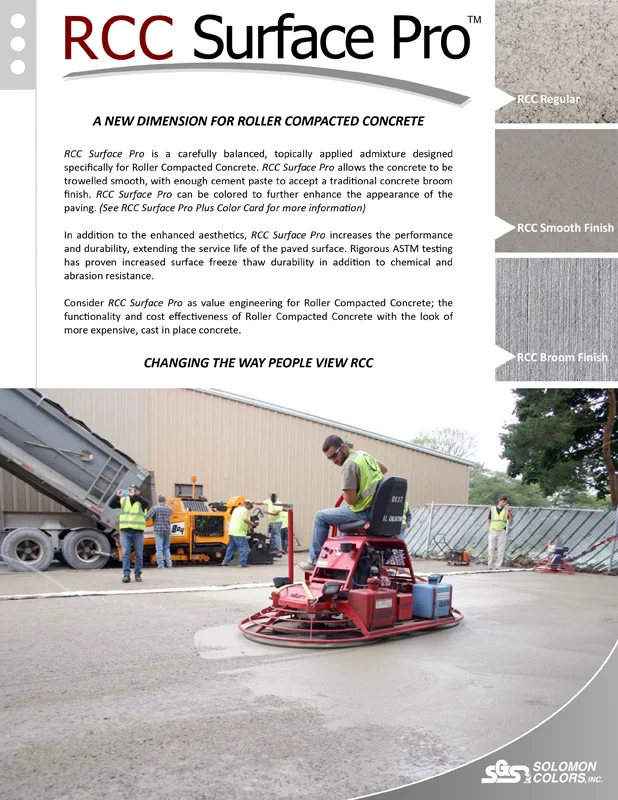

RCC Surface Pro is a carefully balanced, topically applied admixture designed specifically for Roller Compacted Concrete. RCC Surface Pro allows the concrete to be trowelled smooth, with enough cement paste to accept a traditional concrete broom finish. RCC Surface Pro can be colored to further enhance the appearance of the paving.

RCC Surface Pro Plus TIS

RCC Surface Pro & Plus is a topically applied admixture that increases the performance and workability of Roller Compacted Concrete. A proprietary blend of amorphous silica interacts with the calcium hydroxide forming additional calcium silicate hydrate (Cement). The chemistry actively enhances the surface to allow trowelling equipment to be used in the finishing of Roller Compacted Concrete.

RCC Surface Pro / Plus SDS

RCC Surface Pro - Pre Bid Information

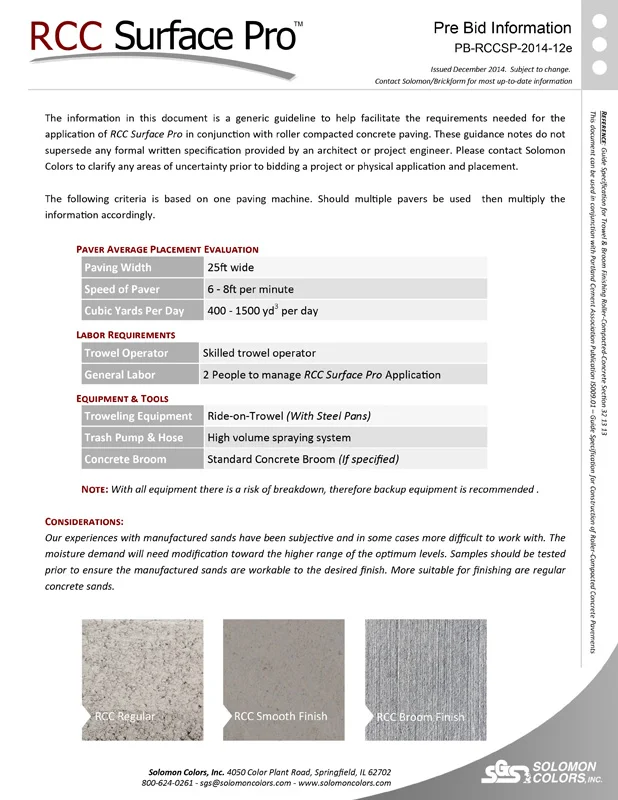

The information in this document is a generic guideline to help facilitate the requirements needed for the application of RCC Surface Pro in conjunction with roller compacted concrete paving. These guidance notes do not supersede any formal written specification provided by an architect or project engineer. Please contact Solomon Colors to clarify any areas of uncertainty prior to bidding a project or physical application and placement.

RCC Surface Pro Independent Test Results

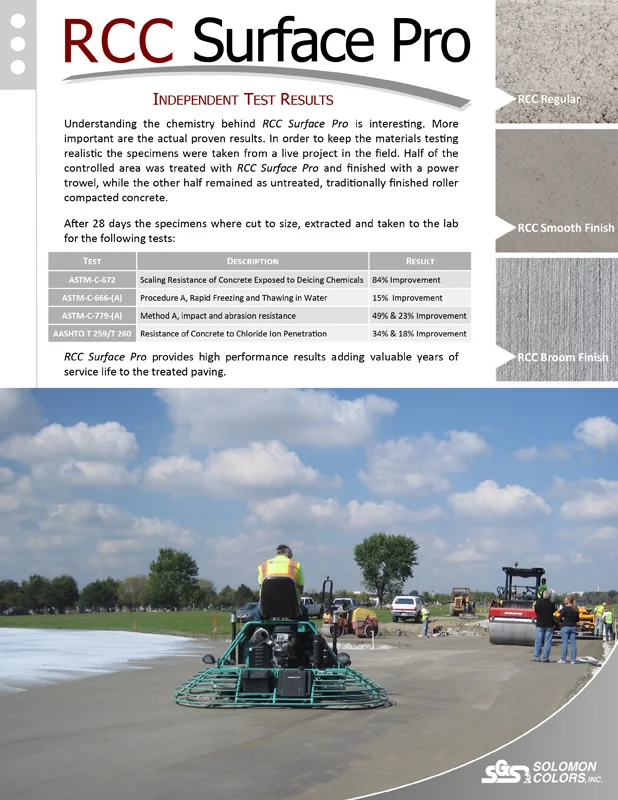

Understanding the chemistry behind RCC Surface Pro is interesting. More important are the actual proven results. In order to keep the materials testing realistic the specimens were taken from a live project in the field. Half of the controlled area was treated with RCC Surface Pro and finished with a power trowel, while the other half remained as untreated, traditionally finished roller compacted concrete.

Nelson Testing Laboratories Results

Hardened concrete specimens were delivered to NTL for testing on August 7, 2014 by Solomon Colors. All specimens were cut from larger concrete slabs by Litgen Concrete Cutting & Coring. All concrete was placed on June 26, 2014 using traditional roller compacted concrete methods and coated with IDOT 309 White Cure. Half of the specimens were extracted from an area that was treated with RCC Surface Pro, a topically applied admixture applied at a rate of 100 to 150 sf/gallon. The control specimens were taken from an area that was untreated. All specimens were from the same concrete slab and placed using the same methods and mix design.