Clean Sweep

Featured in the August 2014 issue of Concrete Products Magazine. RCC Surface Pro was used at the Maryhill Catholic Cemetery new Chicago. The project is the maintenance yard for all the earth moving equipment and storage. After a small trial of RCC Surface Pro the project owners decided to go ahead with a broom finished roller compacted concrete surface.

Enjoy the article and if you want to stop by and see the project feel free. The client is happy for visitors to call in to review the RCC paved area.

The Source

Featured January 2015

Public Works - Special Issue

Featured 2014

ACPA Guide Specification

This document provides a guideline specification useful for developing project specifications for roller compacted concrete (RCC) as an exposed RCC pavement surface, that may or may not be diamond ground for smoothness and/or texture. RCC as a base/subbase layers is not covered in this specification. The information is also not wholly applicable for non-pavement applications such as backfills, dams or liners. This guideline should not be used as a specification reference in contract documents. An owner, engineer or contractor must consider the available options and apply these guidelines to create specifications for specific local projects.

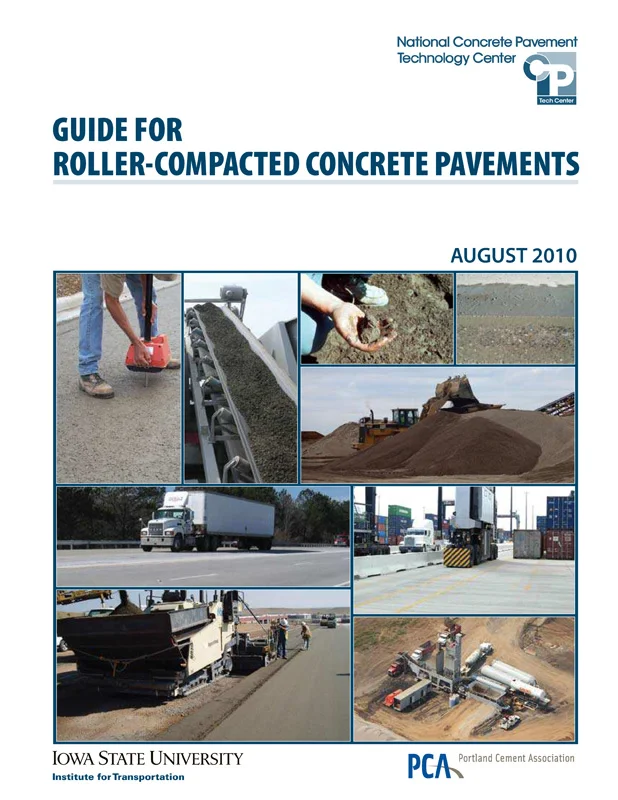

Guide for Roller-Compacted Concrete Pavements

This Guide for Roller-Compacted Concrete Pavements is a product of the National Concrete Pavement Technology Center (National CP Tech Center) at Iowa State University’s Institute for Transportation, with funding from the Portland Cement Association. This guide provides owner-agencies, contractors, materials suppliers, and others with a thorough introduction to and updated review of RCC and its many paving applications. It includes detailed overviews of RCC properties and materials, mixture proportioning, structural design issues, and production and construction considerations, plus troubleshooting guidelines and an extensive reference list.

Automakers Drive Acceptance of Roller-Compacted Concrete

For years, one of the uses of roller-compacted concrete (RCC) has been to create simple, fast and economical pavements for industrial and heavy-duty applications. Placed with conventional asphalt paving equipment and incorporating the same basic materials as regular concrete, RCC pavements create safe, durable surfaces for ports and loading docks, intermodal transit facilities, parking lots, military facilities, and storage yards.

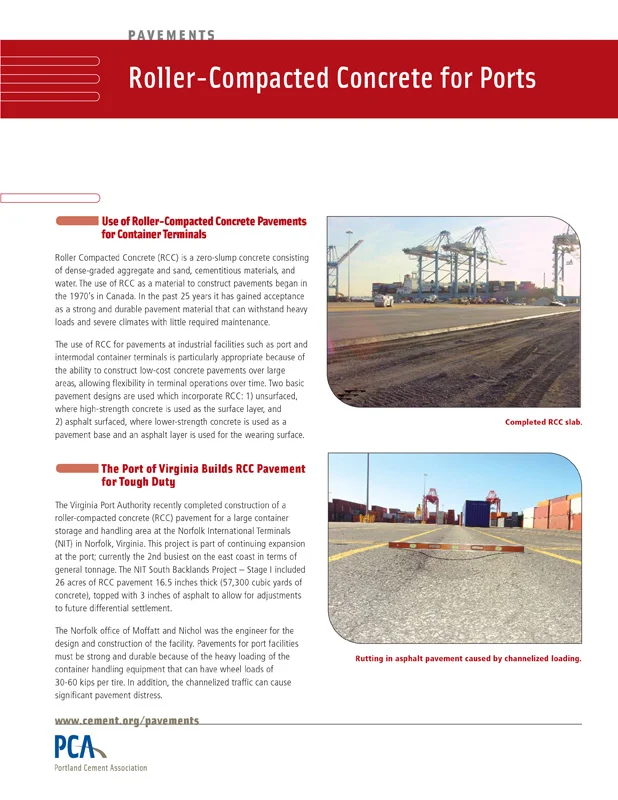

Roller-Compacted Concrete for Ports

Roller Compacted Concrete (RCC) is a zero-slump concrete consisting of dense-graded aggregate and sand, cementitious materials, and water. The use of RCC as a material to construct pavements began in the 1970’s in Canada. In the past 25 years it has gained acceptance as a strong and durable pavement material that can withstand heavy loads and severe climates with little required maintenance.

Frost Durability of Roller-Compacted Concrete Pavements

Over the years, roller-compacted concrete (RCC) has been used successfully for the construction of industrial pavements such as log sort yards, military hard stands, or container yards. In the area of industrial applications, RCC has proven to be extremely competitive compared to high-performance asphalt pavements. Even if its share of the global road-construction market remains relatively marginal in North America, RCC now increasingly is used for the construction of pavements exposed to very severe loading and environmental conditions. This growing interest in RCC has prompted contractors and engineers to come up with technical innovations. Placement and consolidation operations have been improved significantly over the years, and new mixture design methods that allow the production of RCC mixtures with optimum packing densities (and minimal binder contents) have been developed recently. Particularly in eastern Canada, high-performance RCC mixtures with a 7-day compressive strength of 55 MPa and a 7-day flexural strength of 7 MPa now are used regularly for the construction of full-scale jobs.

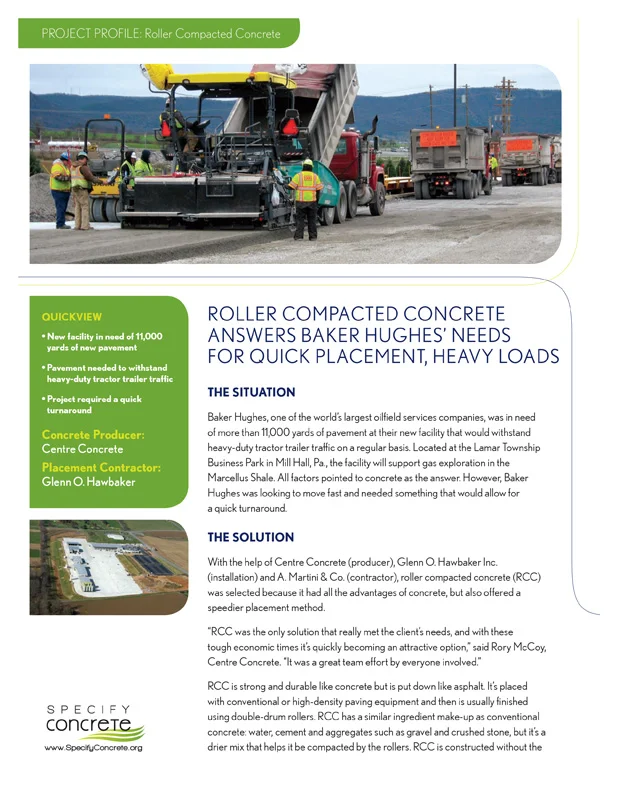

Roller Compacted Concrete Answers Baker Hughes' Needs for Quick Placement, Heavy Loads

Baker Hughes, one of the world’s largest oilfield services companies, was in need of more than 11,000 yards of pavement at their new facility that would withstand heavy-duty tractor trailer traffic on a regular basis. Located at the Lamar Township Business Park in Mill Hall, Pa., the facility will support gas exploration in the Marcellus Shale. All factors pointed to concrete as the answer. However, Baker Hughes was looking to move fast and needed something that would allow for a quick turnaround.

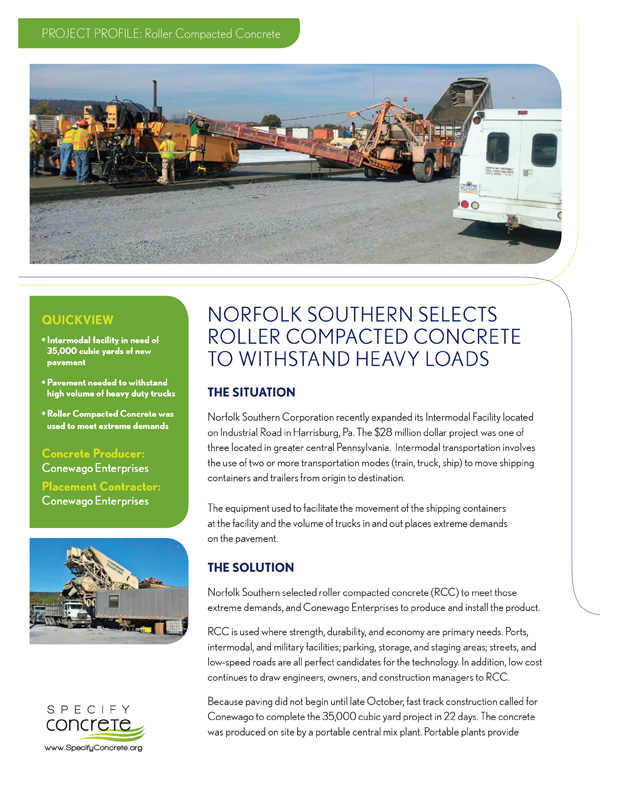

Norfolk Southern Selects Roller Compacted Concrete to Withstand Heavy Loads

Norfolk Southern Corporation recently expanded its Intermodal Facility located on Industrial Road in Harrisburg, Pa. The $28 million dollar project was one of three located in greater central Pennsylvania. Intermodal transportation involves the use of two or more transportation modes (train, truck, ship) to move shipping containers and trailers from origin to destination. The equipment used to facilitate the movement of the shipping containers at the facility and the volume of trucks in and out places extreme demands on the pavement.

Roller Compacted Concrete Provides Cost-Saving Solution to Sycamore Street Project

In Upper Nazareth Township, Pa, a segment of Sycamore Street had completely failed due to inadequate pavement strength. The road was so cracked it looked like a dried creek bed. Various repair methods were assessed, including: cold-in-place recycling (CIP); full-depth reclamation (FDR); and full-depth reconstruction using conventional asphalt pavement.

Roller Compacted Concrete

Roller Compacted Concrete (RCC) is an ultra-tough, no-slump concrete that is placed with conventional or high-density paving equipment and usually finished with double-drum rollers. RCC is a perfect marriage of strength, durability, and light reflectivity. It’s constructed without the joints, forms, dowels or steel reinforcing which is typically needed with conventional concrete, making it a strong, fast and economical solution.

RCC got its start in the logging industry back in the 1970s, when the industry was looking for a paving material that could stand up to massive loads and specialized equipment – but still be constructed quickly and economically.